-

Initial material comes from lunar regolith (polar or mare sites with proven accessibility). Regolith is excavated, crushed, sieved to micron-scale, baked to drive off volatiles, and electrostatically sorted for clean, glassy/silicate grains. Phase-2 adds small-asteroid feedstock once tugs and depots are in routine use.

-

Target grain sizes ~0.5–10 µm. Options include straight-through sieving, melt-sprayed microspheres for tighter size control, and thin dielectric coatings for charge management. QC sensors measure grain size distribution and optical properties before loading.

-

Two launch modes: (A) electromagnetic mass-driver “buckets” loft sealed canisters to cislunar capture orbits; (B) small chemical landers lift canisters to a depot (e.g., NRHO). Both minimize gravity-well penalties and enable steady, scalable throughput.

-

Cargo is captured at a depot and transferred to solar-electric tugs (ion/Hall). Depots provide power, comms, packaging, and traffic coordination. Tug convoys stage loads and depart to L1 on staggered schedules to keep the injectors continuously supplied.

-

Time depends on propulsion and alignment. Chemical tug: ~3–10 days in favorable geometry (near new-moon), ~1–3 weeks typical. Solar-electric tug: ~4–12 weeks with far higher propellant efficiency. Schedules are planned so inventories at L1 stay >30–60 days of buffer.

-

At L1, canisters dock to “feed hoppers.” Vacuum augers and metering wheels deliver grains to electrostatic conditioners that set/neutralize charge and de-clump. Inline optical sensors verify mass flow and opacity contribution before grains enter the injector throats.

-

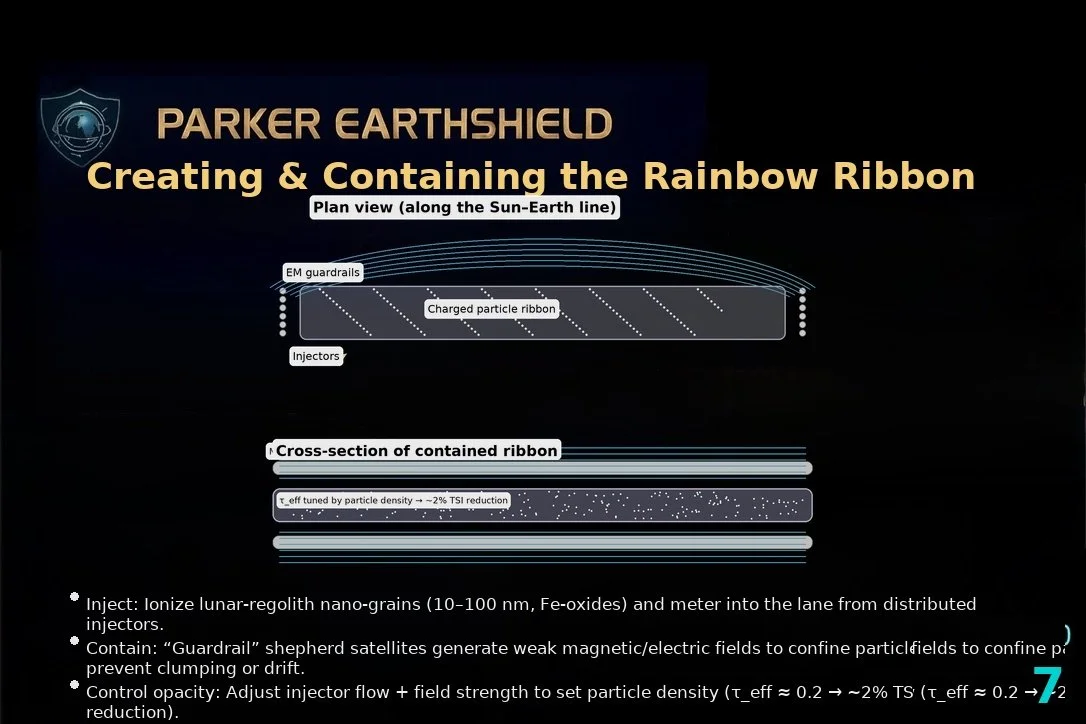

Each injector is a variable-aperture nozzle/electrostatic lens that launches a gently diverging sheet of grains on pre-computed ballistic paths through the target column. Multiple injectors interleave “fans” to fill the column uniformly without over-densities.

-

We don’t “trap” dust; we maintain a flow. Weak EM shepherds and small radiation-pressure vanes trim the column’s shape, while a feedback controller adjusts injection rate, trajectory mix, and grain sizes to hit the desired attenuation. The result is a stable, tunable column that resists drifting apart because fresh grains continually replace those exiting.

-

Trajectories are chosen so grains cross the column then drift away from Earth-orbital traffic lanes. Keep-out zones and automated deconfliction are enforced around spacecraft corridors. If needed, shepherds apply tiny nudges to deflect strays out of sensitive regions.

-

“Off switch” = stop injection. Without replenishment, solar radiation pressure and gravity disperse the cloud on short-to-moderate timescales (weeks to a few months, grain-size dependent), returning insolation to normal. Emergency fast-drop protocols reduce injector flow within minutes.