-

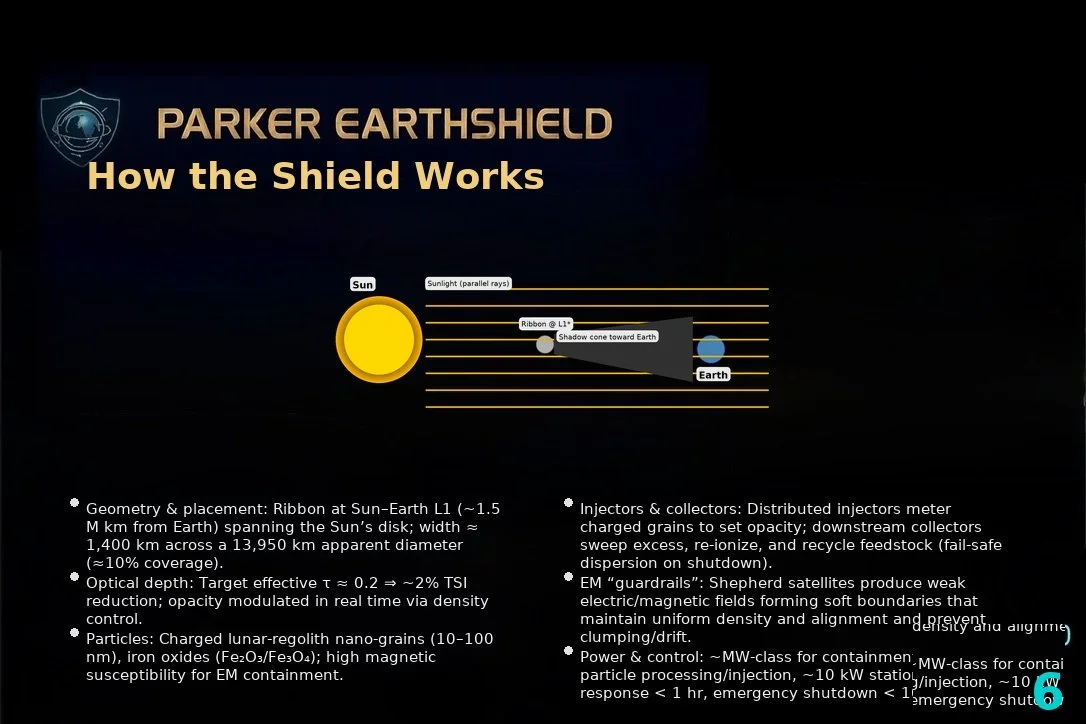

A flowing, replenished column of micron-scale particles centered on the Sun–Earth line near L1. Instead of a rigid shade, the cloud slightly attenuates sunlight (target ~1.5–2%) before it reaches Earth, with density maintained by controlled injection and gentle field shaping.

-

We work with celestial mechanics, not against them. Particles follow stable ballistic paths through a target zone; we regulate how many pass through per second. No massive structure to hold in place, easier scaling, and inherently reversible by stopping the feed.

-

Multiple “fountain” injectors stream dust along trajectories that traverse the desired column. Small, local electromagnetic fields and radiation-pressure shaping nudge particles for better coverage and uniformity—like lane guides for traffic rather than a barrier.

-

Fountain injectors (near L1 or offset stations), guidance/shepherd craft, solar-power and comms, and a real-time control loop tied to optical/infrared sensors. Early stages use Earth-launched material; later phases can source from the Moon or small asteroids.

-

We tune the cloud’s effective optical depth by adjusting injection rate, grain size distribution, and trajectory mix. Seasonal or emergency controls are possible: increase flow for extra cooling, reduce or pause for rapid roll-back.

-

Space-based spectrometers and imagers continuously measure column density and angular extent. A simple controller compares measured attenuation to the target and updates injector settings automatically, with human-in-the-loop governance.

-

Silicate or glassy grains from lunar regolith analogs are promising; alternatives include engineered dielectric or carbon-based particles. Micron-scale grains balance scattering efficiency with controllability; mixes can be tailored for performance and lifetime.

-

The stream is shaped to avoid Earth-orbital traffic lanes and to minimize long-lived debris. If we stop injection, solar radiation pressure and gravity disperse the cloud on short to moderate timescales (weeks–months depending on grain size), providing a hard failsafe.

-

Begin with a small column whose integrated attenuation is equivalent to a ~1-km disk. Objectives: validate injection/guidance control, measure real attenuation vs. predictions, exercise the governance switch-off, and refine scaling laws for full deployment.